The right production solution for

a wide range of industries

The name imoberdorf stands for durable, robust, metal-cutting quality systems that produce high-quality small and micro parts in large quantities extremely precisely and quickly. Our demand for perfection covers the entire production process. That is why we only use premium components in our machines.

Due to the almost unlimited application possibilities, Imoberdorf production solutions are used in a wide range of industries.

Automotive industry/

E-mobility

E-mobility

Electronics

Hydraulics & Pneumatics

Compressors

Medical/

Dental technology

Dental technology

Locking technology

Watch industry

Automotive industry/E-Mobility

Experience the future of driving with our innovative and sustainable solutions

Today, more than ever, cars are technical masterpieces. In order to meet the performance and safety requirements, all components, right down to the smallest, must be manufactured with extreme precision and in the highest quality.

With Imoberdorf production machines, you can machine car components such as joint forks, ABS components, transmission parts or cooling elements in large quantities and with the greatest precision.

Quality means safety.

Electronics

Revolutionise your everyday life with our smart and connected solutions

In the electronics industry, precision and quality are essential to meet the high performance and safety requirements of electronic devices and components. With our state-of-the-art production technologies and quality controls, you produce electronic components of the highest precision and reliability in high volumes.

Hydraulics & Pneumatics

Discover the power of hydraulic and pneumatic solutions from us

In the hydraulic and pneumatic industry, reliability and quality are crucial to meet the high demands of plants and machines in terms of performance and safety. With our state-of-the-art production processes, you produce hydraulic and pneumatic components of the highest precision and durability.

Compressors

Efficiency, performance and reliability as a guarantee for success

Compressors ensure that heat is extracted from the air in a refrigerator or a car air conditioning system and thus cools it. However, a compressor only functions reliably if the components used are manufactured and assembled with extreme precision.

Our flexibly configurable systems produce high-precision connecting rods, pistons and crankshafts in large quantities and with short cycle times.

Let our experts implement a solution tailored to your company.

Quality shows in the detail.

Medical/Dental technology

For innovative solutions with the highest quality standards

In the medical and dental industry, precision and quality are crucial to ensure the best possible treatment and safety for patients. Our flexibly configurable systems produce high-precision medical instruments, implants and dental components in high volumes and with short cycle times. Let our experts implement a solution tailored to your company.

Quality shows in the detail.

Locking technology

Safety requires high precision, we can help with that

In a security lock, a world opens up in the smallest of spaces, in which technical precision is combined with intelligent design - and possibly electronics - in such a way that unauthorised opening becomes massively more difficult, if not impossible.

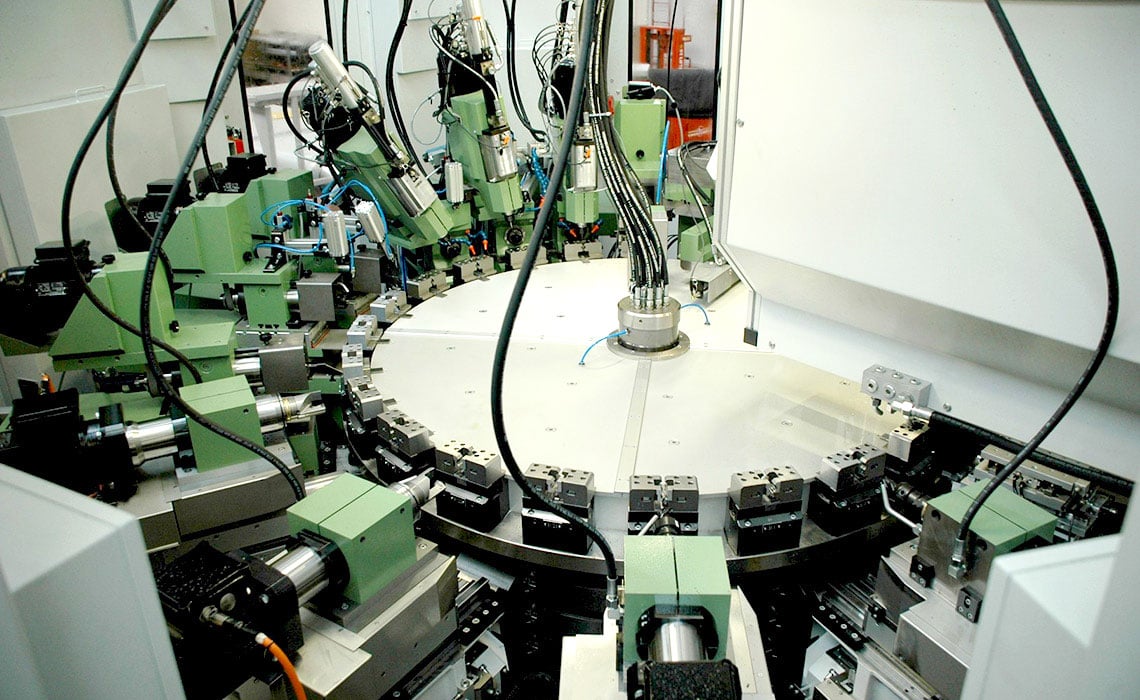

Imoberdorf rotary indexing systems are designed in terms of precision, productivity and flexibility to produce components for door locks in large quantities with extreme precision and short cycle times.

The key lies in precision.

Watch industry

Clockworks, like our systems, are a marvel of technology. Fascination with functionality!

Watch movements are among the most complex, precise and filigree things that can be produced mechanically.

Since the development of the first rotary transfer machine for watch components in 1953, imoberdorf has constantly pursued the goal of building systems that set new standards in terms of productivity, flexibility and precision - while remaining compact in terms of construction and design.

In this way, plates, bridges, crowns and other watch parts can be manufactured with high precision, flexibility and in large quantities. Your demand for quality is our trademark.

News from our industry

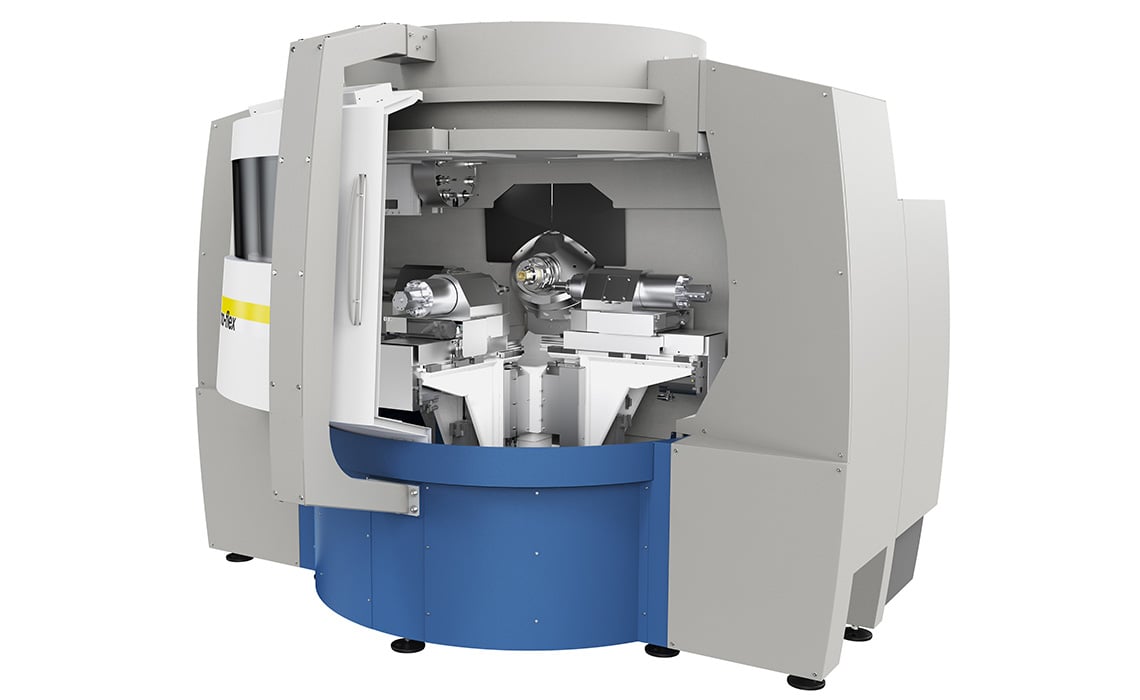

Our new flagship "imo-flex"

-1920x910-HG_Weiss-Banner-Haupseite_1140x700.jpg?width=1140&height=700&name=NEU_2023_01-(63043-821_Werkzeug_1)-1920x910-HG_Weiss-Banner-Haupseite_1140x700.jpg)

Flexible solutions with high accuracy and dynamics

Safe into the future with imoberdorf AG customer service

You might also be interested in

Production solutions

Discover our wide variety of products.

Technologies

Discover what makes our systems unique.

About us

Discover what characterises us as imoberdorf AG.

Career

Discover the career opportunities with us.