The strength lies in simplicity

The best solutions are often the simplest. We want to make processes or systems as simple as possible to make them more efficient and reliable. Simple designs require less maintenance and are easier to repair if something does go wrong.

Simple operations allow the user to work faster and more accurately, increasing productivity.

Simple solutions usually require fewer resources and are therefore cheaper to purchase and maintain.

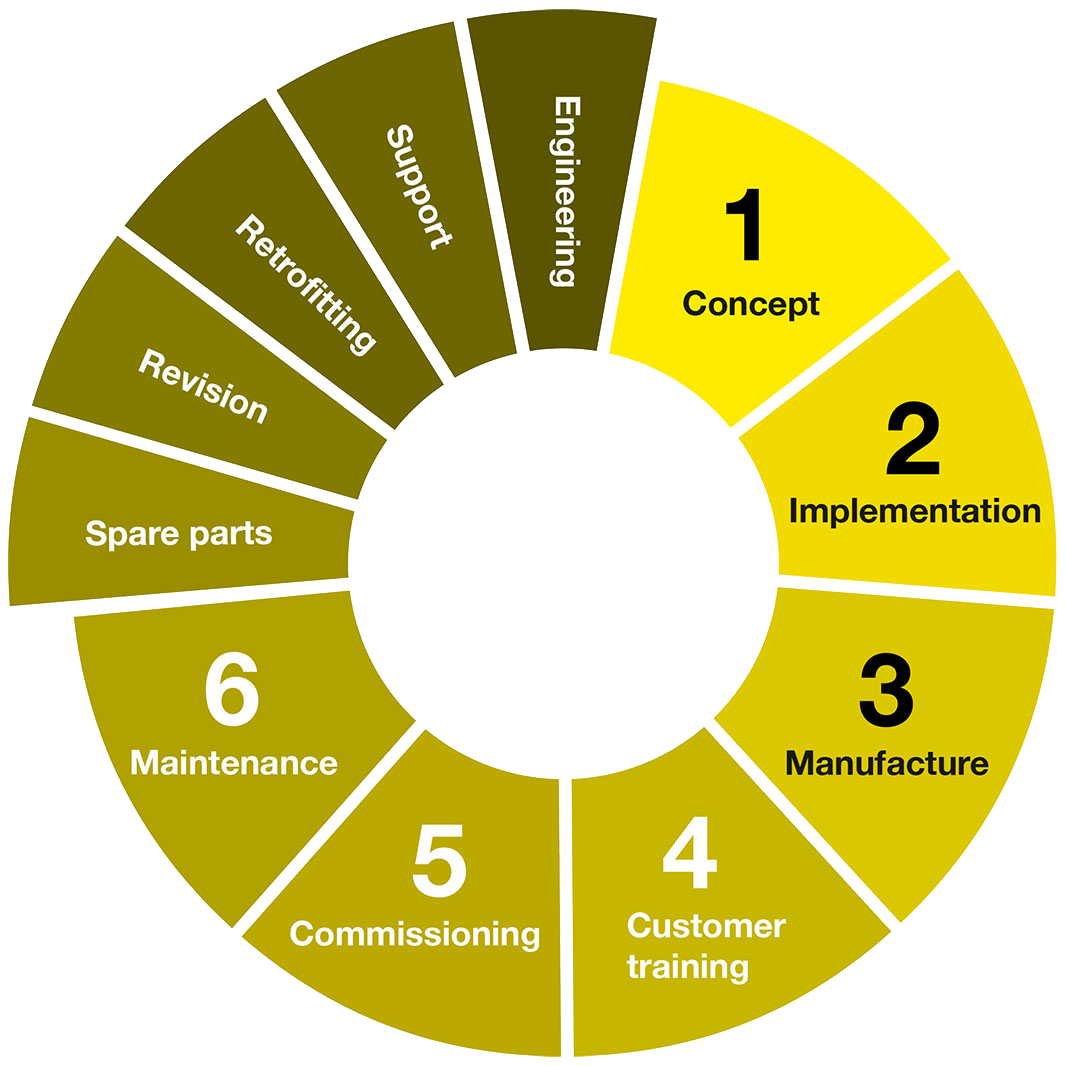

Customised production solutions from a single source

At the centre of every production solution manufactured by Imoberdorf is the customer's requirement. You specify the desired parameters in therms of precision, flexibility and productivity, and everything else is handled by Imoberdorf. Our expertise covers all the steps from conception and implementation to the manufacture and commissioning of your production solution.

You receive a complete solution from a single source.

Series production - we know how to do it!

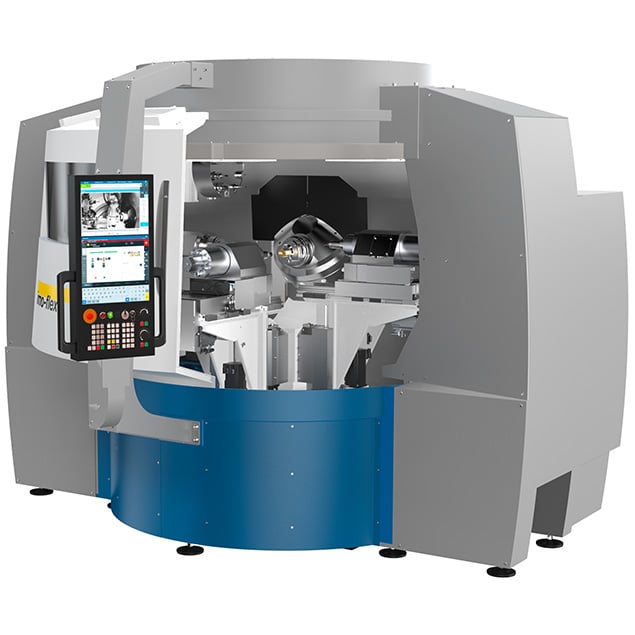

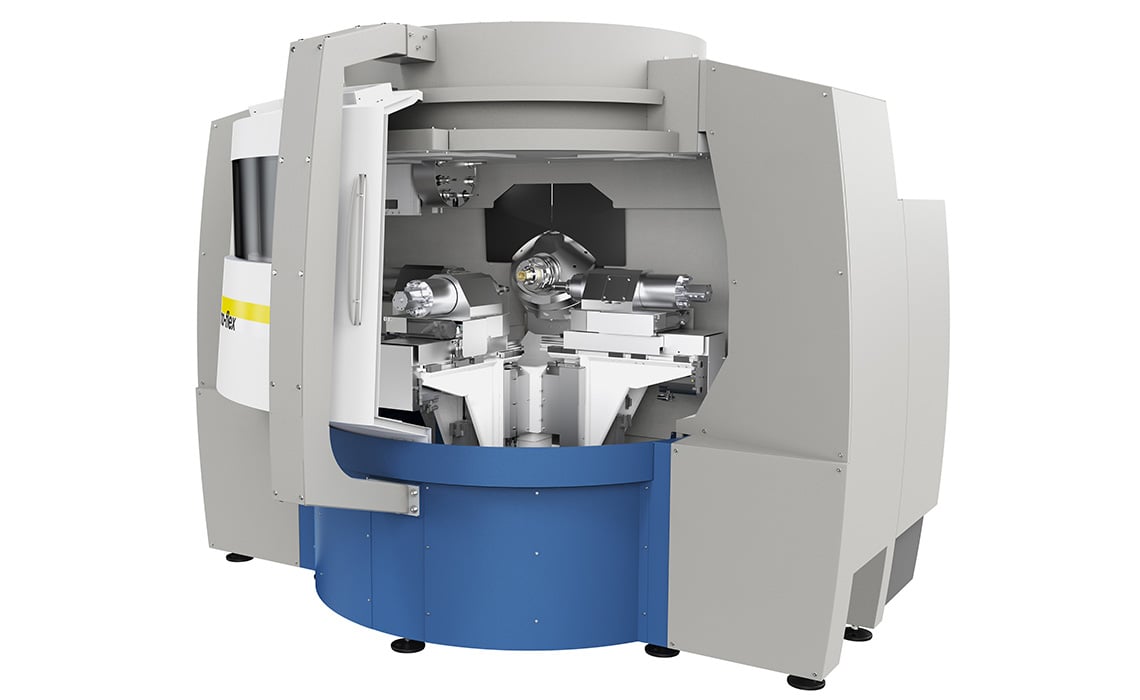

imo-flex

Our latest line, the imo-flex offers maximum flexibility paired with high productivity for smaller and medium batch sizes. The kinematics are the same as on our rotary transfer machines, which means that the entire process experience can be transferred 1 to 1. With up to 3 machining stations and a 10-fold tool changer above each unit and an optional 50-fold chain changer, the imo-flex offers space for up to 80 tools.

The imo-flex is designed to be extremely space-saving and the interfaces are designed to allow flexible linking of several machines. This means that additional units or infeeds and outfeeds can be used several times. Efficient and ecological production can thus be lived!

Your advantages:

- Maximum flexibility

- Extremly individual use

- Proven kinematics

- Space for up to 80 tools

- Linking of several imo-flex possible

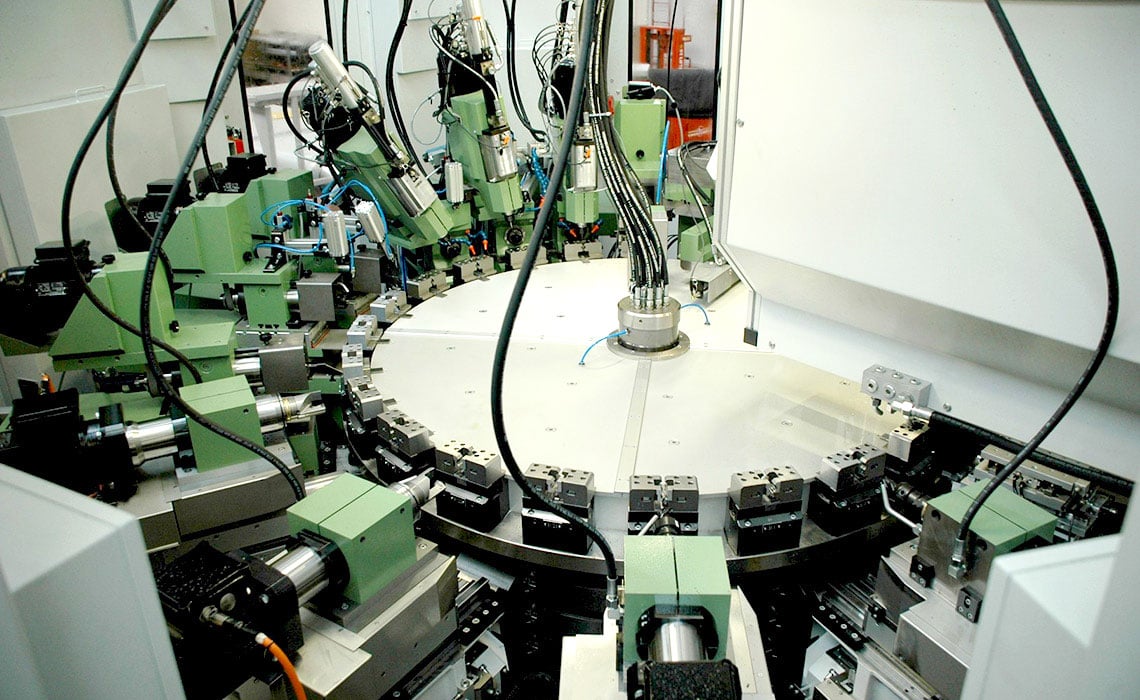

Highest productivity with imo rotary transfer systems

Rotary transfer machines are an important part of industrial production as they enable high productivity. A key advantage of imo rotary transfer machines is that they have a high repeatability and throughput rate. This leads to higher productivity and reduces production costs.

Another advantage of imo rotary transfer machines are their flexibility. The ability to easily adapt the machine to the needs of the product means that the machine can be used for a wide range of products. This enables a more efficient use of the machine and secures the purchase costs.

Overall, imoberdorf rotary transfer machines offer high productivity, flexibility and reliability. They are therefore the right choice for industrial production.

imo-compact

Our imo-compact solution is extremely space-saving, ergonomic and efficient. Designed for complete series production with up to 8 standard machining stations (or up to 20 compact machining stations). The stations are equipped with our up to 4-axis machining units. A wide variety of spindle configurations (vertical/horizontal, parallel, offset), tool changers, (pneumatic) plug gauges, 3D measuring probes are available. Complemented by our standard clamping systems, a wide range of proven technology modules is created. The software modules we have been developing in-house for decades round off our expertise as a mechanical engineering company.

Your advantages:

- The repeat accuracy is ± 3 μm

- Individual loading/unloading handling

- Individual complete solution

- Extremly space-saving

- Up to 8 processing stations possible

imo-smart

The imo-smart, as the name implies, is our intelligent solution when it comes to cleverly machining a complex customer workpiece for complete series production. With up to 12 machining stations, it brings the necessary machining diversity to produce the workpieces according to customer requirements. The stations are equipped with our up to 4-axis machining units. A wide variety of spindle configurations (vertical/horizontal, parallel, offset), tool changers, (pneumatic) plug gauges, 3D measuring probes are available. Supplemented by our standard clamping systems, a wide range of proven technology modules is created. The software modules we have been developing in-house for decades round off our expertise as a mechanical engineering company.

Your advantages:

- The repeat accuracy is ± 3 μm

- Individual loading/unloading handling

- Individual complete solution

- Machining of small to large parts

- Up to 12 machining stations possible

imo-space

The imo-space offers, as the name suggests, a very large workspace. There is room for up to 16 machining stations with up to 45 or more spindles - the production potential is enormous.

The stations are equipped with our up to 4-axis machining units. A wide variety of spindle configurations (vertical/horizontal, parallel, offset), tool changers, (pneumatic) plug gauges, 3D measuring probes are available. Complemented with our standard clamping systems, a wide range of proven technology modules is created. The software modules we have been developing in-house for decades round off our expertise as a mechanical engineering company.

Your advantages:

- The repeat accuracy is ± 3 μm

- Individual loading/unloading handling

- Individual complete solution

- Very large working area

- Up to 16 machining stations possible

Conventional technology

The use of state-of-the-art CNC technology is not always justified. For simpler applications, one- or two-axis machining units are often sufficient. Thanks to our many years of experience, we have direct access to an enormous pool of conventional technologies from our company. Be it for machining units with hydraulic feeds, quill spindles, pure PLC controls, etc. The scope of various individual possibilities is almost limitless.

We are happy to accept special enquiries for MB-5 rotary transfer machines or Posalux rotary transfer machines.

Your advantages:

- The repeat accuracy is ± 3 μm

- Individual loading/unloading handling

- Individual complete solution

- Cost-efficient refit solution

- Latest PLC control possible

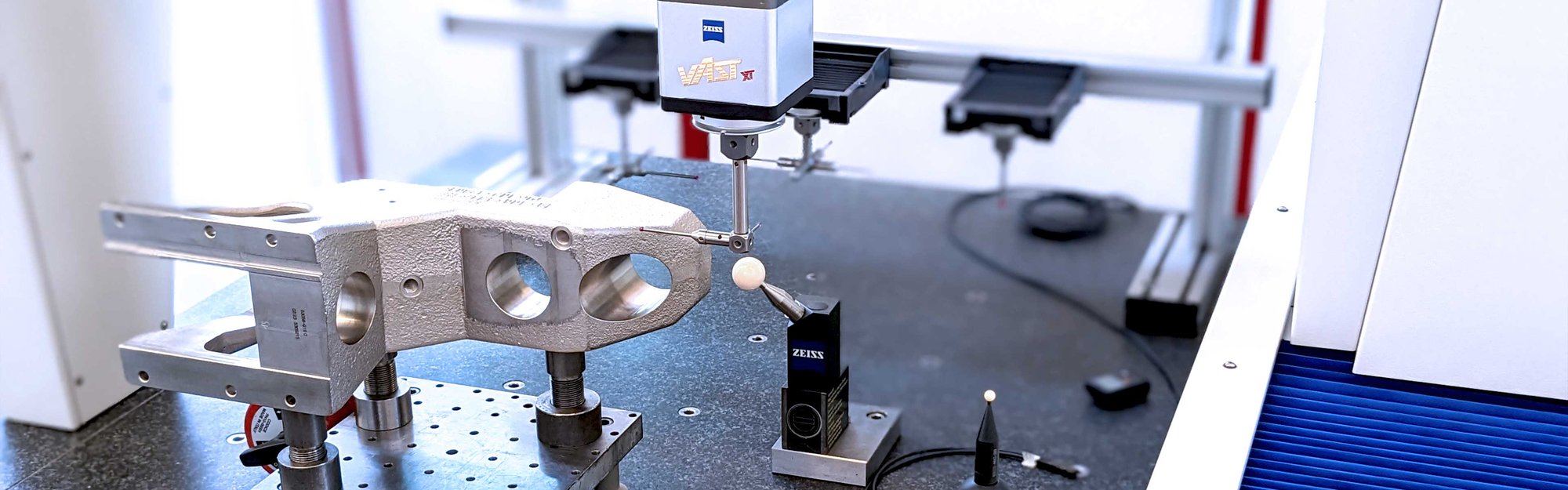

Our quality standards

Our quality standards are of utmost importance to us. We strive to meet the highest requirements in terms of materials, manufacturing technologies and processes to ensure that our products and services meet the highest quality standards. We are committed to ensuring that our customers are completely satisfied with our products and services and are constantly working to improve our quality processes.

News from our industry

Our new flagship "imo-flex"

-1920x910-HG_Weiss-Banner-Haupseite_1140x700.jpg?width=1140&height=700&name=NEU_2023_01-(63043-821_Werkzeug_1)-1920x910-HG_Weiss-Banner-Haupseite_1140x700.jpg)

Flexible solutions with high accuracy and dynamics

Safe into the future with imoberdorf AG customer service

You might also be interested in

Technologies

Discover what makes our systems unique.

Industries

Discover the industries in which our machines are used.

About us

Discover what characterises us as imoberdorf AG.

Career

Discover the career opportunities with us.